In the coming months, the Semi-Conductor Lab, or SCL Mohali, will benefit from the largest infusion of capital in its history: a corpus of ₹4,500 crore from the India Semiconductor Mission (ISM) to modernise its operations. Even as it gains these funds, though, it will not be at the cutting edge of the chip ecosystem in India — which it was before a devastating fire in 1989 — as large fabrication and packaging units backed by domestic conglomerates and international chipmaking majors are ramping up more cutting edge operations.

SCL Mohali was established in 1983, and started operations the subsequent year, as a part of a national strategy to lead in the global semiconductor race. However, in 1989, as a fire broke out in the facility, SCL lost its lead, and has since been far from the cutting edge that countries like Taiwan and Japan have managed on the chipmaking front. Ajai Chowdhry, one of the founders of Hindustan Computers Ltd (HCL), pointed out in a 2023 book that SCL was India’s “sole fabrication plant.” Mr. Chowdhry mentioned that SCL was under the administrative purview of the Department of Space as recently as 2023.

This underlines what SCL’s relatively limited role so far in this century: the fab’s customers have mainly been the Union government itself, with PSUs like ISRO and the DRDO placing their trust in the unit’s so-called “legacy” chips over any imported product. Since large systems like train bogeys and satellites typically require hundreds of chips, and miniaturising these systems it not as big a concern as it is for personal electronics like smartphones, SCL chips have found a place in many indigenous engineering projects.

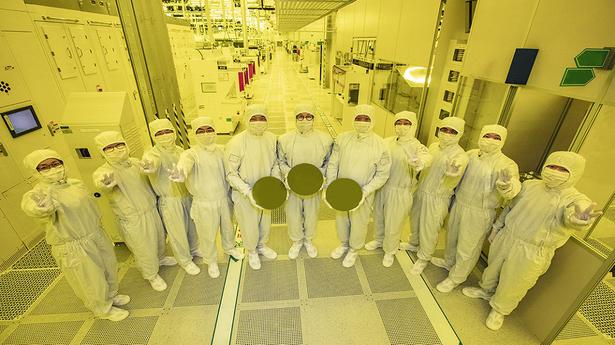

Minister of State for Electronics and Information Technology Jitin Prasada said in response to a Lok Sabha question on December 17 that the facility has chip design, quality testing, fabrication facilities, and “robust systems for power supply, ultra-pure water, clean air and specialised gases required for chip manufacturing.”

Mr. Prasada said that the modernisation funds, announced on November 28, would entail a “large-scale increase in production capacity, targeting 100 times production of wafers from the current level. IT Minister Ashwini Vaishnaw publicly requested the Government of Punjab to provide land adjacent to the SCL complex as a part of this modernisation — the plot on which SCL sits was originally provided for a token ₹1.

Modern chips, which produce integrated circuits at single-digit nanometre scales, are billions of dollars of investment away from SCL’s current capabilities, one official told The Hindu, given that technologies like extreme ultraviolet photolithography are controlled by a handful of firms who lead the cutting edge. Mr. Chowdhry wrote in his 2023 book that there would still be a massive role that SCL could play, even if it wasn’t leading from the front; one example he cited was chips used in LED bulbs.

“The value of the Indian LED lighting market stood at 2.754 billion dollars in 2021, and the IMARC Group projects that it will reach 9.658 billion dollars by 2027,” Mr. Chowdhry wrote. A domestic push to grow the domestic manufacturing of hundreds of millions of such chips, he said, would “automatically create demand for upcoming semiconductor ATMP units in India and the SCL Fab”.

“It must be kept in mind that the chips required for most generic products are fairly low-level,” Mr. Chowdhry added in the book, Just Aspire. “The semiconductor shortage [during the COVID-19 pandemic] brought home the importance of the trailing-edge spectrum of chip technology. It is these low powered chips used for pedestrian functions that command large volumes.”

With capital subsidies for domestic firms like Tata Electronics Pvt Ltd and international firms like Micron Technology, Inc., which are working on more modern semiconductor nodes — such as 28 nanometres — SCL is not in the running for the cutting edge, and may not be even after its modernisation. Under the Chips 2 Startup (C2S) programme, however, it is emerging as a key stop for chip designers and electronics design students, whom the facility is helping with “taping out” their creations, fabricating them on their behalf.

Published – December 24, 2025 05:50 am IST